Views: 1288 Author: Site Editor Publish Time: 2019-05-01 Origin: Site

Recently we received feedbacks from our customers who produce aluminium aerosol cans that their aluminium aerosol can bottom exterior wall comes with pitting corrosion with phenomenon: paiting film bulge and pilling off, aluminium can weight reduction. The aluminium aerosol can production process include: aluminium slug-extrusion-washing-paiting-drying-necking. There are corrosion holes and black spots on the aluminium spray can exterior stripped painting film. In order to figure out the failure cause of the corrosion, we researched into the aspect of aluminium slug material, corrosion appearance and elements, production parameters, etc.

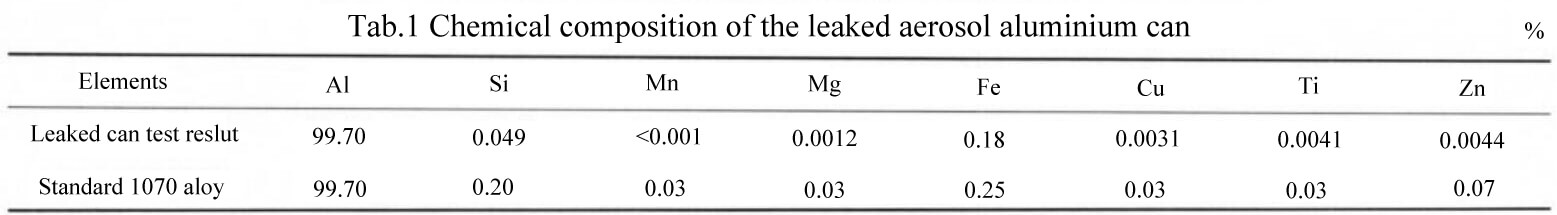

1. Chemical Inspection

We analyzed the chemical composition of the leaking aerosol can and compared it with standard 1070 aluminium alloy elements as below Tab. 1

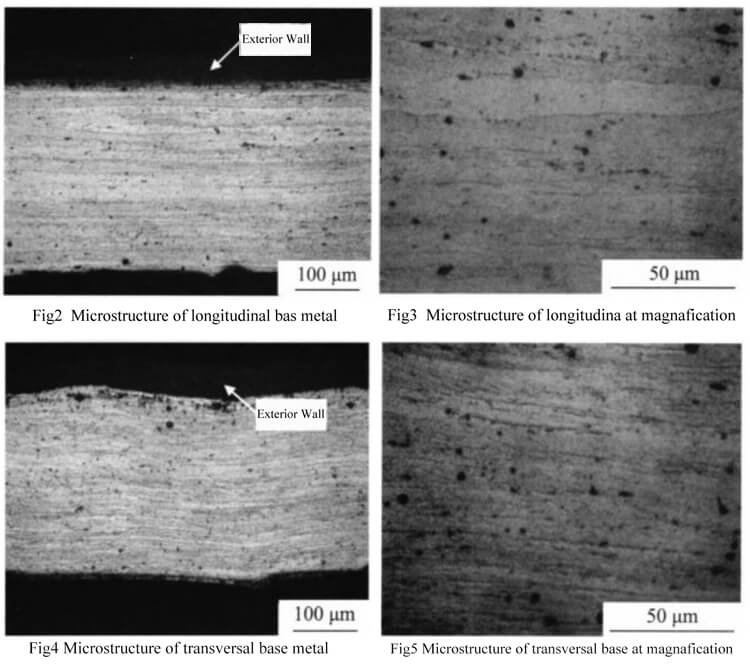

Sampling on the vertical and parallel direction of the aerosol can body, the metal base structure presences α phase plus little particle phase, and the metal grain is prolonged. The aluminium can wall thickness is app. 0.30mm, exterior paiting film thickness 40~80μm and the inner painting film thickness is about 10μm, shown as Fig.2~5

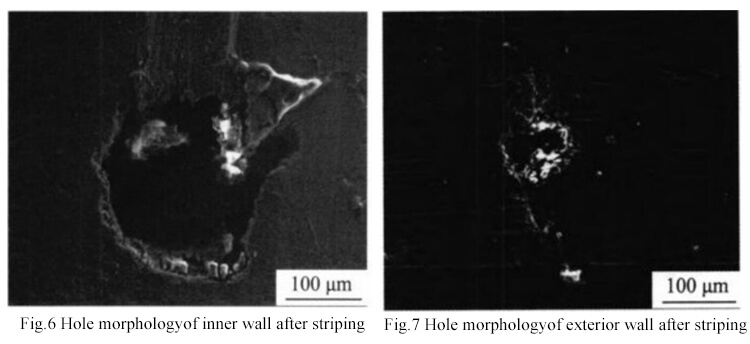

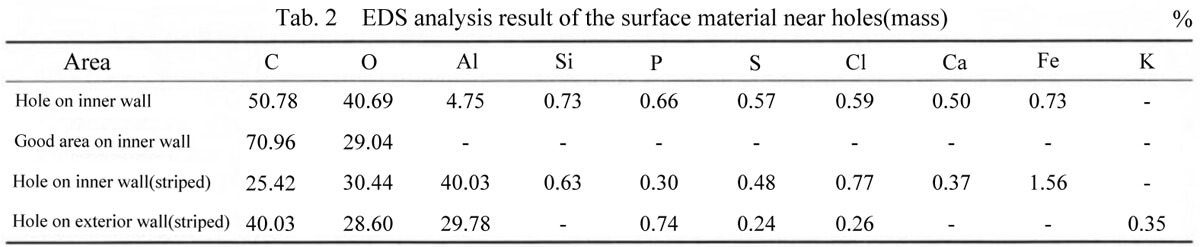

There are massive organic objective film found on the surface of both inner and exterior aerosol can wall. And there are explicit holes among the leaking areas. The inner and exterior holes are one-one correspondent. The hole size on the inner wall is app. 0.22mmx0.24mm and the holes on the exterior wall measures 0.09mmx0.10mm, the corrosion holes on inner wall are apparent larger than that of exterior wall and the edge structure of holes are loose Fig.6 and Fig.7 shows. By the test of EDS, as the Tab.2 shows, we observed much S,Cl,P and other corrosive elements and impurities like Fe,Si,Ca,etc around the holes, except massive Carbon, Oxygen elements.

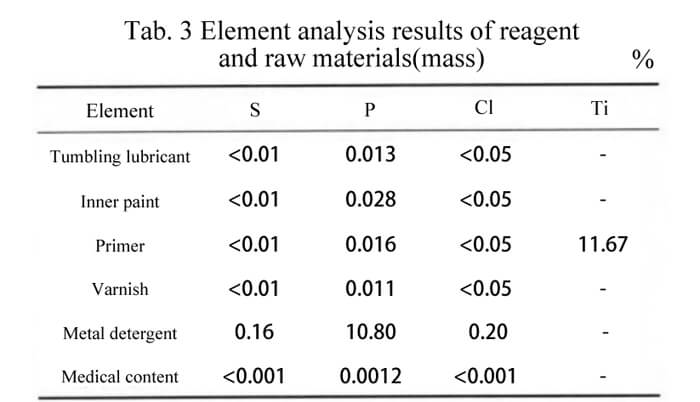

The analysis on the reagent material used in aerosol can production procedure and S,P,Cl element examination result is shown on Tab.3

The chemical composition analysis on the aerosol can show the aluminium material complies to standard 1070 alloy. The microscopic structure is monotony of α phase with little particle phase existed and metal grain spread along the rolling direction. And much corrosive elements like S,P,Cl found around the hole edge by electron microscope and the corrosive elements exist on the hole after film stripping and cleaning. Meanwhile, there are S,P,Cl element contents in the metal cleaning solution and there few of these corrosive mater in other reagents.

The aerosol can are produced by extrusion on the aluminium slugs and the aerosol can corrosion types mainly include uniform corrosion, pitting corrosion, perforation, crevice corrosion, galvanic corrosion, stress corrosion crack and underfilm corrosion. The pitting corrosion is a most common corrosion phenomenon. The Cl particle is a serious corrosion accelerator to aluminium alloys. When the aluminium surface absorbed living anionic Cl- the surface oxide film on the aluminium can be broken easily. The broken part became electronic dipole anode and unbroken parts became anionic dipole, which composites passivation-activation device and lead to aluminium can pitting corrosion as final consequence.

Therefore the S,P,Cl elements shall residue on parts of the aluminium can surface if the washing solution were not removed cleanly and the painting on the aluminium aerosol can inner wall is very thin which is easy to be cracked or broken by corrosive elements, meanwhile, the liquid contents in the spray can shall enforce the corrosive effect. So the corrosive leaking on the aerosol can is caused by the above whole process.

1) The aluminium aerosol can pitting corrosion is caused by residue of washing solution used in production process. The S,P,Cl elements in washing solution breaks the oxide film of aluminium surface and lead to aluminium container leak.

2) In order to solve this kind of corrosion problem, we suggest to keep strict control on the aluminium can washing process and exchange the washing solution in time.